Matt Silver Paper, a specialty paper that combines a metallic texture with understated aesthetics, not only attracts attention with its sophisticated gray-silver tone but also conveys a delicate, warm, and restrained tactile experience through its unique

- +86-13320349063

- 1546099403@qq.com

- No. 30-33, No. 45, Shiqiaopu Shixin Road, Jiulongpo District, Chongqing

- Home

-

Our Services

- Coated Paper

- Synthetic Paper

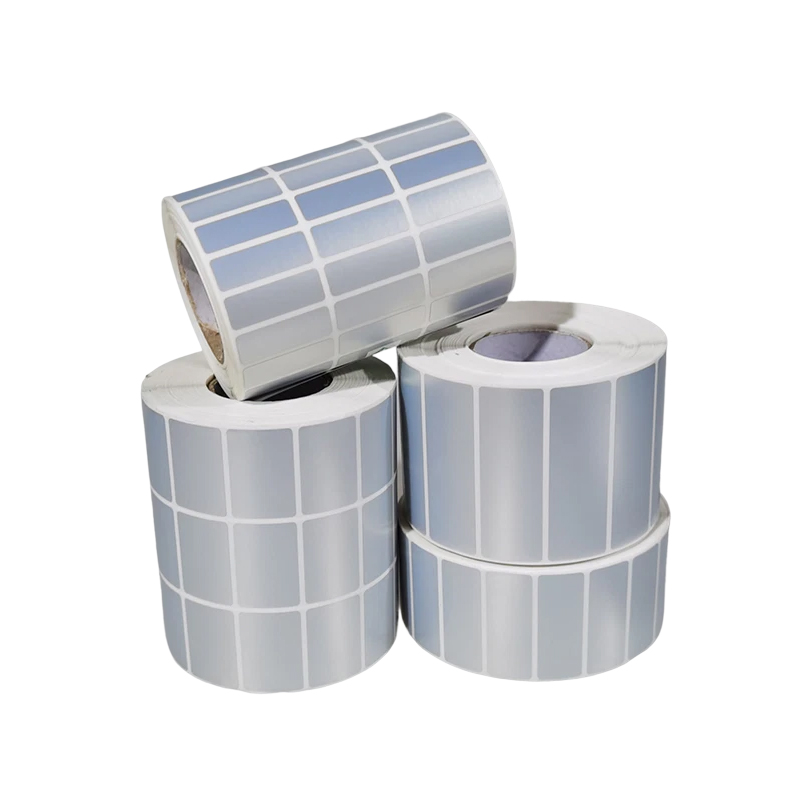

- Matt Silver Paper Label

- Light Silver Brushed White Background

- Silver Brushed Blue Background

- White Pet Label

- Color Printed Label

- Light Silver Brushed Blue Checkered Background

- Removable Label

- Thermal Synthetic Paper

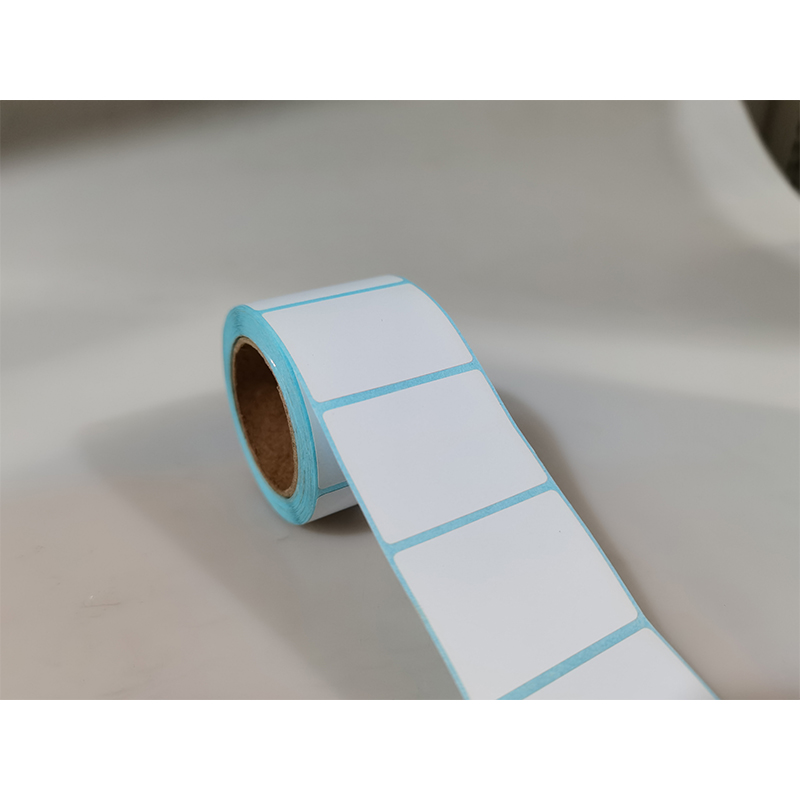

- Thermal Paper

- Double Layer Synthetic Paper

- Double Coated Paper

- Wax Ribbon

- Enhanced Mixed Base Ribbon

- Full Resin Ribbon

- Display

- Solutions

- News

- About

- Partners